Exploring Global Trends in Injection Mold Companies

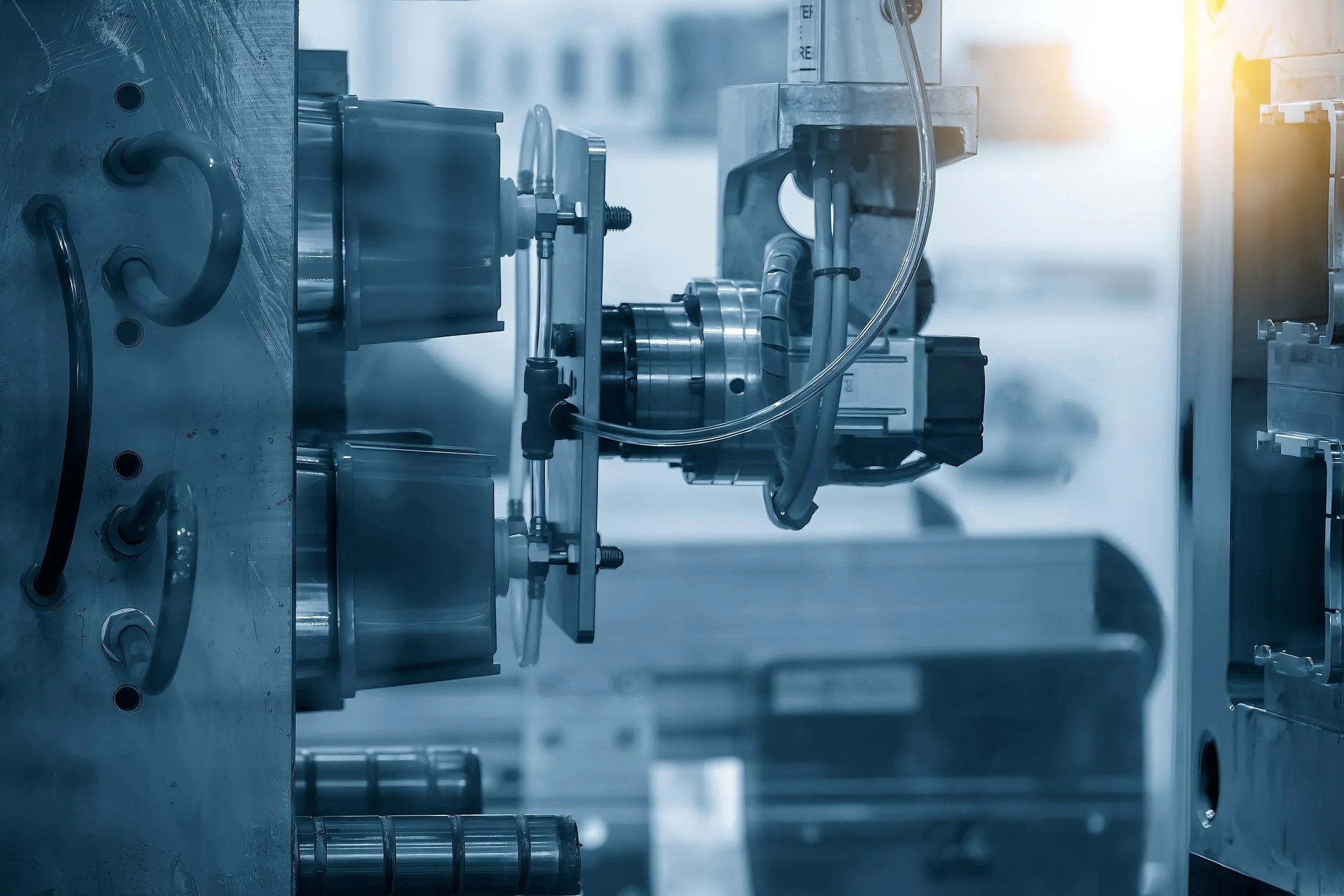

The injection molding industry has undergone major transformations in recent years. Injection mold companies are the leading players in manufacturing processes and are constantly changing to technological advancements and global trends that impact how products are designed, produced, and delivered.

Two trends reshaping the future of injection molding today are automation and 3D printing; manufacturers can meet growing demand, increase efficiency, and decrease costs. We will look at how these trends are affecting injection mold companies and the future of the manufacturing industry.

Injection Molding: Rise of Automation

Robotic systems, AI-driven processes, and automated machinery are becoming more and more common in injection mold companies. Automation not only cuts labor costs, but precision and human error are reduced, and the parts are more consistent and of high quality.

The main advantage of automation is that it is able to streamline production. Repetitive tasks like part removal, inspection, and packaging can be handled with automated systems, allowing human workers to concentrate on more complex tasks. For example, robotic arms can quickly take molded parts off of injection molds and deposit them directly into packaging, which speeds up turnarounds and increases productivity.

Additionally, automation enables better monitoring of production processes. Injection mold companies can now track real-time parameters such as temperature, pressure, and cycle times with the help of advanced sensors and control systems. Manufacturers can optimize production, predict potential failures, and reduce waste, improving both efficiency and sustainability with this data.

The Role of 3D Printing in Injection Molding

In recent years, 3D printing has emerged as a powerful tool for injection mold companies. This technology, sometimes referred to as additive manufacturing, involves creating three-dimensional objects by layering materials based on a digital model. For injection molding, 3D printing has opened up new possibilities in prototype development, mold design, and even production itself.

One of the most significant ways 3D printing influences injection molding is through the creation of rapid prototypes. Traditionally, producing prototypes for injection molding could take weeks or even months, depending on the complexity of the part. With 3D printing, injection mold companies can quickly produce prototypes in a matter of days, allowing designers and engineers to test and refine their designs much faster than before. This accelerates the overall product development process, allowing companies to bring products to market more quickly.

Another area where 3D printing is making waves is mold creation. Injection mold companies can now use 3D printers to create complex and intricate mold designs that would be difficult to achieve using traditional machining methods. 3D printing also allows for the production of metal molds, which are highly durable and capable of withstanding high pressures and temperatures, making them ideal for mass production.

3D printing enables more cost-effective and flexible manufacturing. Injection mold companies can create low-volume, customized parts without the need for expensive and time-consuming tooling processes. This is particularly beneficial for industries that require custom-made parts or short production runs, such as medical devices or aerospace components.

The Future of Injection Mold Companies

As automation and 3D printing continue to evolve, injection mold companies are expected to embrace even more innovative technologies. The integration of AI and machine learning into molding processes could lead to smarter systems that automatically adjust production parameters to optimize efficiency and quality. Additionally, the ongoing development of sustainable materials and eco-friendly processes will likely become a central focus for manufacturers aiming to reduce their environmental footprint.

Another important trend is the growing demand for personalized and custom products. Consumers are increasingly seeking unique, tailored products, and injection mold companies are responding by offering more flexible and customizable manufacturing options. Automation and 3D printing are key enablers of this shift, allowing companies to efficiently produce small batches of personalized items without the need for large-scale retooling.

Conclusion

Injection mold companies are navigating a rapidly changing landscape. Automation and 3D printing are driving efficiencies, reducing costs, and opening up new possibilities for design and production. As these technologies mature, they will become more and more important to the future of the manufacturing industry, fueling innovation and opening up exciting opportunities for businesses and consumers alike.