How Plastic Injection Mold Makers Are Supporting Modern Industries

Plastic injection molding is an important manufacturing process that has revolutionized countless industries. This process works by inserting molten plastic material into a cavity, where it cools and solidifies into the desired shape. This diverse technique can mass produce complex and high-quality plastic parts with precision and efficiency. This blog will discuss how plastic injection mold makers are at the forefront of this industry and why their work is so important.

Facilitating Innovation in Industries

The plastic injection mold makers are in a central position to foster innovation across different industries. In this way, they help product designers and engineers to implement innovative concepts into practice.

Plastic injection mold makers fill the gap between design and production and are crucial in turning innovative ideas into reality. Product designers and engineers work together with them to optimize designs for manufacturability so they function cost-effectively. Their material expertise allows them to choose the right polymers for application-specific needs, prototyping, and iterative testing of concepts before mass production.

Mold makers use precision engineering and advanced tooling to enable complex designs with tight tolerances so that they can be scaled and production challenges are minimized. They are central to driving innovation across industries by streamlining processes, cutting costs, and accelerating time to market.

Automotive Industry

The automotive industry depends heavily on plastic injection molding makers to produce a broad range of components, including:

Interior parts: Dashboards, door panels, consoles, and seat components

Exterior parts: Bumpers, fenders, grilles, floor rails, and headlight housings

Engine components: Intake manifolds, valve covers, and oil pans

Electronics Industry

The electronics industry utilizes plastic injection mold makers to create intricate components like:

Enclosures: Phone cases, tablet cases, and laptop cases

Connectors: USB ports, HDMI ports and power connectors

Internal components: Heatsinks, printed circuit boards, and fan shrouds

Medical Industry

The medical industry needs components that are not contaminated and should be made of materials compatible with the human body. Plastic injection molding enables the production of:

Medical devices: Syringes, catheters, and drug delivery devices

Surgical instruments: Handles and components

Diagnostic equipment: Housings and parts

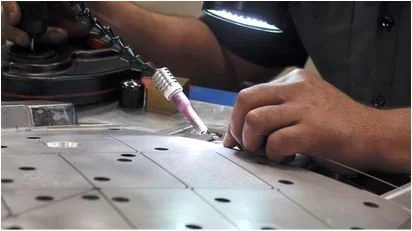

MSI Mold Builders: A Leader in Plastic Injection Molding

MSI Mold Builders is an industry leader in injection molds and offers the finest quality of injection molds. Our mission is to deliver solutions that fulfill the dynamic needs of our customers, including providing products manufactured using the most up-to-date machinery. Our highly trained personnel promise to ensure our products always meet the highest quality of workmanship, reliability, and productivity.

Our extensive range of equipment includes CNC mills, milling machines, EDM machines, lathes, grinders, gun drills, injection molding presses, and bridge cranes. These valuable tools allow us to handle numerous projects with ease, from simple to complex. We collaborate closely with our clients to fully understand their specific requirements and provide customized solutions that exceed expectations.

Whether you need a single mold or a complex mold system, MSI Mold Builders is your trusted partner. It is our promise to continuously supply exceptional products and services that drive success in the plastics industry.