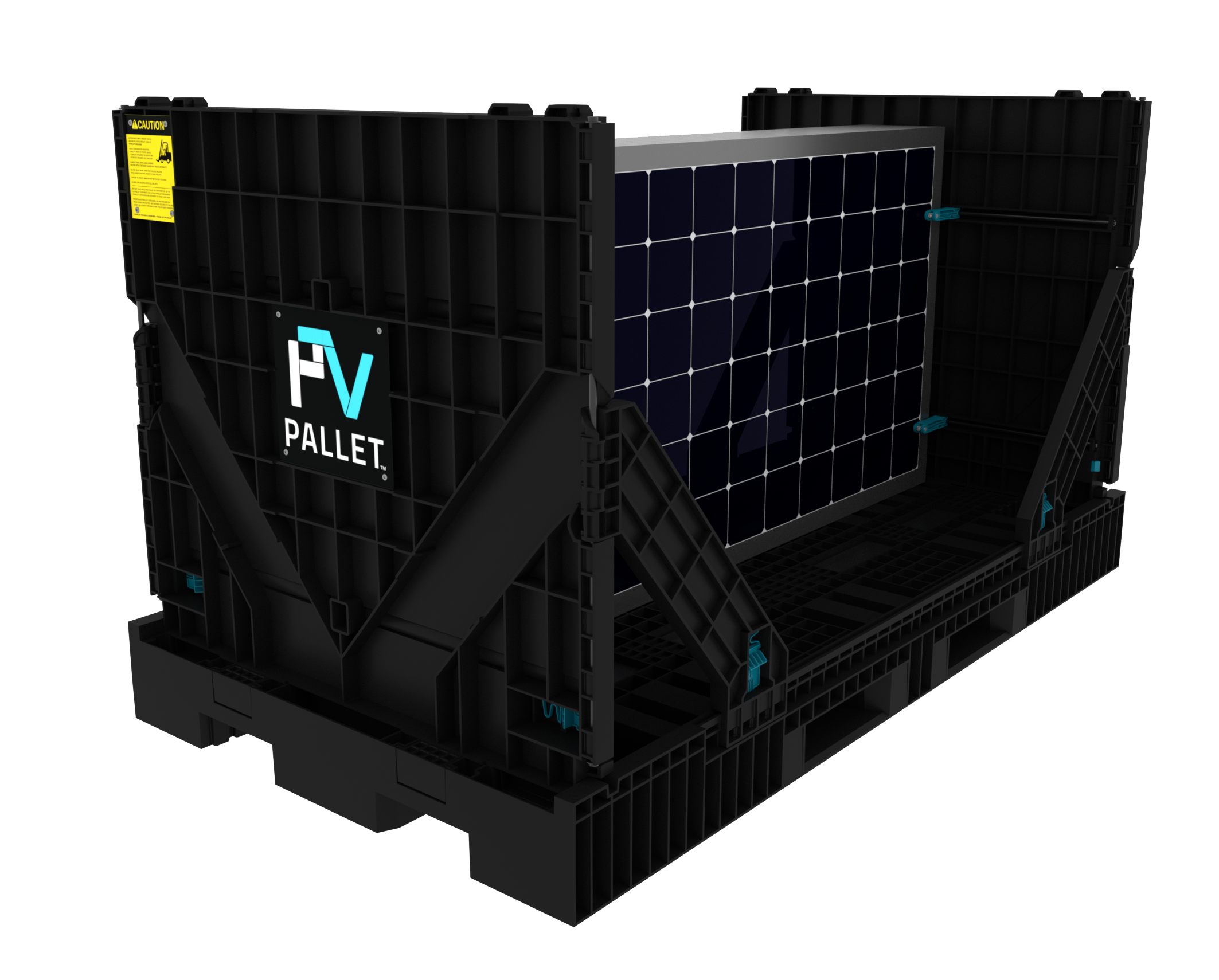

Collaboration Delivers Solar’s First Reusable, Collapsible Pallet Solution

PVpallet provides innovative, reusable packaging solutions that reduce waste, promote reusability, and improve lifecycle economics to the solar industry. Founded to help solar companies become more sustainable, the company identified an issue with the shipping and handling of solar panels. In addition to being prone to rot, traditional, single-use wood pallets pose a safety concern and often result in solar panel damage. PVpallet’s founders had an idea for a better, more sustainable solution – PVpallet Series X, a solar panel pallet made from post-consumer HDPE plastic, reusable, and recyclable at the end of its life cycle.

To transform Series X from an idea to reality, PVpallet needed a partner with expertise in plastics mold manufacturing and the ability to make large, complex molds to meet the product’s size requirements and use parameters. They selected Iowa-based MSI Mold Builders to design, engineer and build aluminum low-pressure foam injection molds for fully reusable and recyclable HDPE pallet bases, side walls, and cross braces.

“The Series X pallet is a large, complex part with many requirements. There are not many mold builders that were able to meet our needs and support our mission,” said Phillip Schwarz, CEO and co-founder of PVpallet. “MSI Mold Builders set themselves apart by demonstrating their capabilities and offering a premium solution from design and engineering through testing and production.”

A recipe for success

Collaboration and ongoing communication were critical to successfully building molds for the pallet. Both companies brought their expertise – PVpallet’s understanding of the solar industry’s needs and performance requirements of the pallet and MSI Mold Builders’ knowledge of the required science and engineering to develop a mold that could sustainably deliver a quality end-product.

The PVpallet team brought a preliminary pallet concept to the table, and through an iterative design process the full team refined the design, improving functionality, meeting functional parameters, and reducing manufacturing cost. Utilizing its proven processes, software, and mold manufacturing experience, MSI Mold Builders determined structural foam molding would achieve the strength, rigidity, and weight requirements, as well as reduce the manufacturing costs.

The team strategized to identify the best way to incorporate steel tubing to eliminate flex in the product and leverage Finite Element Analysis (FEA) to ensure part design was optimized and the product would perform as expected during use. Once the mold designs were finalized, MSI Mold Builders developed prototype molds and conducted a series of tests to ensure all parameters where being met.

Series X Pallet Parameters

Modular pallet base with adjustable walls to accommodate various solar panel sizes

Rigid construction for safety and ability to stack loaded pallets four-high

Eliminate flex in base

Lightweight - high strength-to-weight ratio

When not in use, ship and store flat

Affordable for end user

“PVpallet’s founder brought us in early in the development phase and remained very focused on their mission to eliminate waste streams in the solar industry through innovative, reusable packaging. They were very hands-on and open to feedback, which allowed us to make recommendations and suggestions that resulted in a superior solution to a very complex set of parameters,” said Kyle Klouda, president, MSI Mold Builders.

Delivering the right solution

Together, the companies designed, developed, and produced unique molds that led to the launch of the PVpallet Series X pallet in 2022. The solar panel industry had an enthusiastic response to the new product with customers providing very positive feedback and reporting significant reductions – 90-100% – in solar panel breakage.

This initial product proved the industry was open to and needed this unique solution, confirming the time invested in designing and developing a quality mold was critical for success.

“We couldn’t be happier with the outcome of our work with MSI Mold Builders. Our manufacturing process, which starts with the molds they made, provides a true competitive advantage in the marketplace, while helping us stay true to our mission,” added Schwarz.

Today, Series X is PVpallet’s signature product, and the company continues to add additional mission-focused packaging and shipping solutions.

“Collaborative projects like this, where we are involved early in the design and development, is where MSI really delivers value. We enjoyed overcoming the challenges this product presented and are proud to support PVpallet’s mission,” concluded Klouda.

Benefits of Structural Foam Molding

Aluminum mold construction for reduced material cost

No manifold needed during production

Increased part strength

Faster manufacturing cycle times

Improved stability and durability

Design flexibility